3-10L Bottle Water Filling Machine

3-10L Bottle Water Filling Machine

Production Description

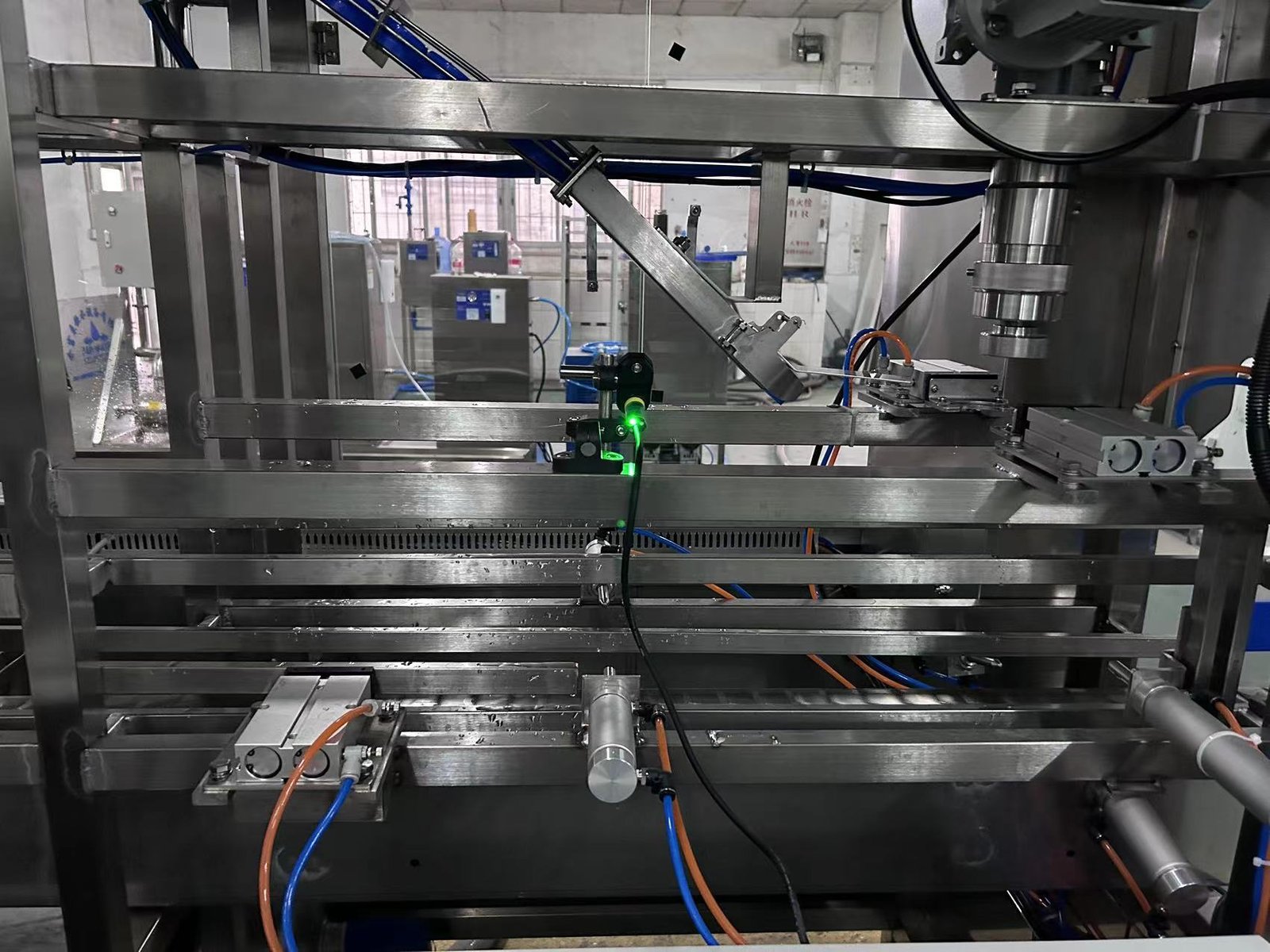

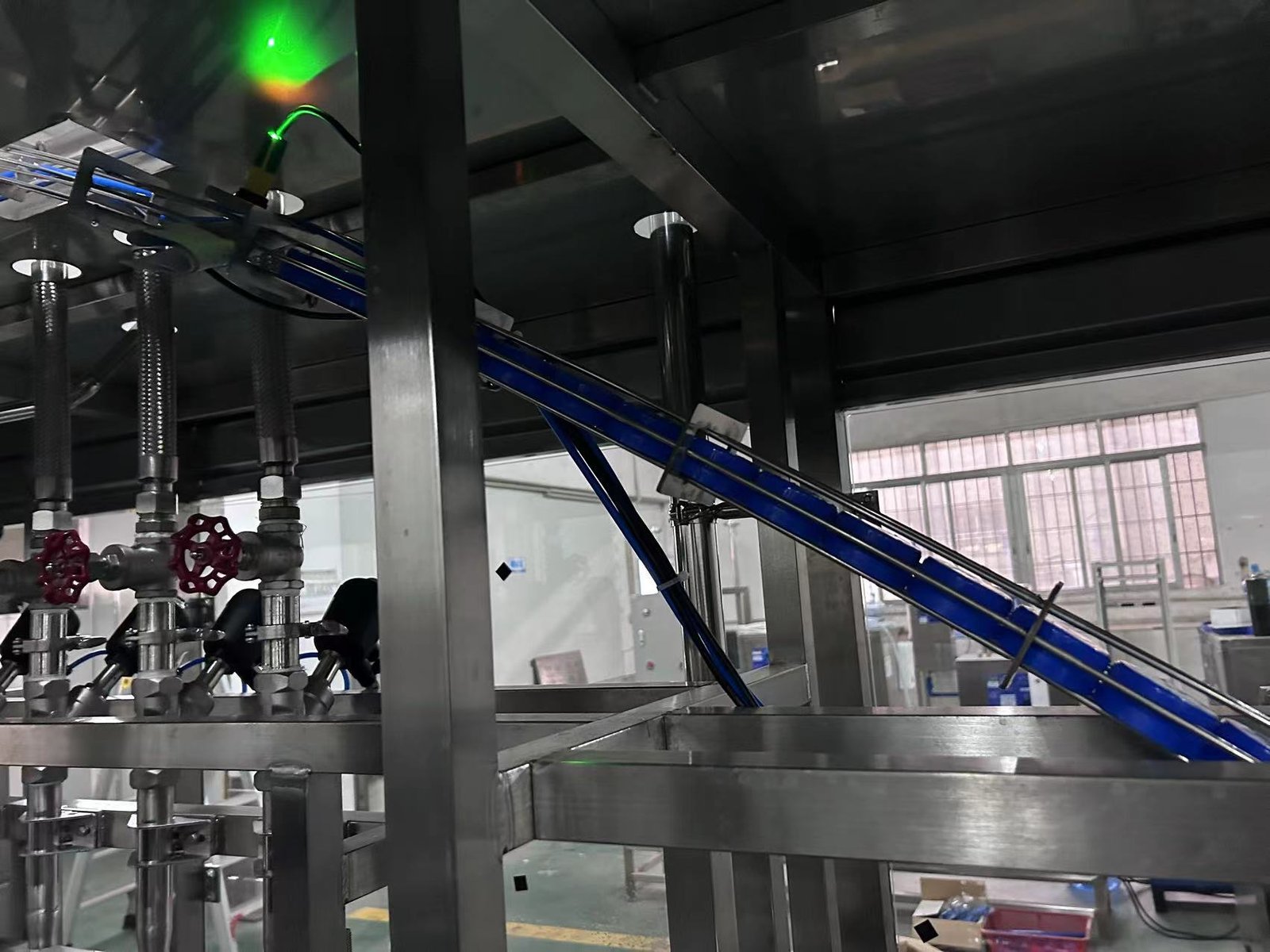

Our 3-10L bottled water production line features a high-efficiency water filling machine designed for medium-capacity water plants, providing stable, accurate, and hygienic filling. Made from food-grade stainless steel, the equipment includes automatic bottle loading, precise water filling, and secure capping functions, ensuring every bottle meets strict quality and hygiene standards. The advanced flow control system minimizes water waste and reduces operational costs, while the user-friendly interface allows easy operation even for beginners. Its compact structure saves space and is suitable for purified water, mineral water, and other types of drinking water. With reliable performance, low maintenance, and high efficiency, this production line helps businesses boost output and improve product quality, making it an ideal solution for expanding or upgrading water bottling operations.

Features and Advantages

It is specially used for filling 3L to 10L bottled water.

It is a good machine line for the all shapes of bottles.

It can be suitable for press cap and screw cap

The machine is designed for bottles such as PVC. PE. PET etc. It can be used for different shape of bottles

The machine line with stainless steel rinse nozzles, pressure filling valve, screw capper, hot steam film shrinkage machine top quality line

Filling time is controlled by the PLC.

The machine adopts high quality stainless steel frame(No. Z304).

The machine design appreance is beautiful, easy operation, maintainence and working stable

The machine’s intelligent control panel offers a user-friendly interface for easy operation and real-time monitoring, allowing you to adjust parameters to meet your specific production needs. Its robust and durable construction ensures long-lasting performance, while its design facilitates easy maintenance, minimizing downtime.

Our Advantages

- User-Friendly

- Food Grade Material

- High-Efficiency

- Energy Efficiency

- Low Energy Consumption

- Advanced Technology

Pre-sales Advice

Our Pre-sales Consultation Services Are Designed To provide You With All The Information.

Installation Service Provided

Online Service And Enginner Oversea Service

Deliver Time

20-60 Days After Receiving The Deposit

Main Technical Parameters

Number | Item | Details | Remark |

1 | Production capacity | 600 bottles/hour | 4-4-1 |

2 | Filling volume | 3L to 10L | |

3 | Number of filling heads | 6 | SUS304 |

4 | Number of capping heads | 3 | SUS304 |

5 | Bottle size | 5L PET bottle | |

6 | Filling precision | 5L±0.1% | |

7 | Air pressure | 0.6-0.8Mpa | |

8 | Air consumption | 30L/MIN | |

9 | Filling water consumption | 3T/H | |

10 | Frame | SUS304 | |

11 | Air cylinder | AIRTAC | Taiwan |

12 | Water pump | Nanfang | Hangzhou |

13 | Electromagnetic valve | Airtac | Taiwan |

14 | PLC | Mitsubishi | Japan |

15 | Power of filing pump | 0.55KW | |

16 | Power of washing pump | 0.37KW | |

17 | Power of cap sorting motor | 0.18KW | |

18 | Total power | 2.25KW | |

19 | Conveyor belt | 4 meters | Including connecting conveyor belt |

20 | Weight | About 700KG |