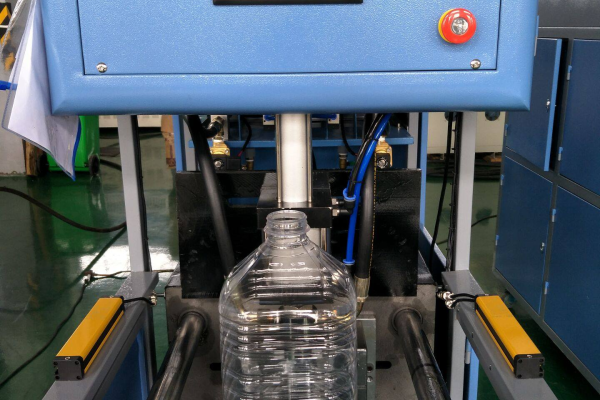

Semi-Automatic 3-10L Bottle Blowing Machine

Semi-Automatic 3-10L Bottle Blowing Machine

Production Description

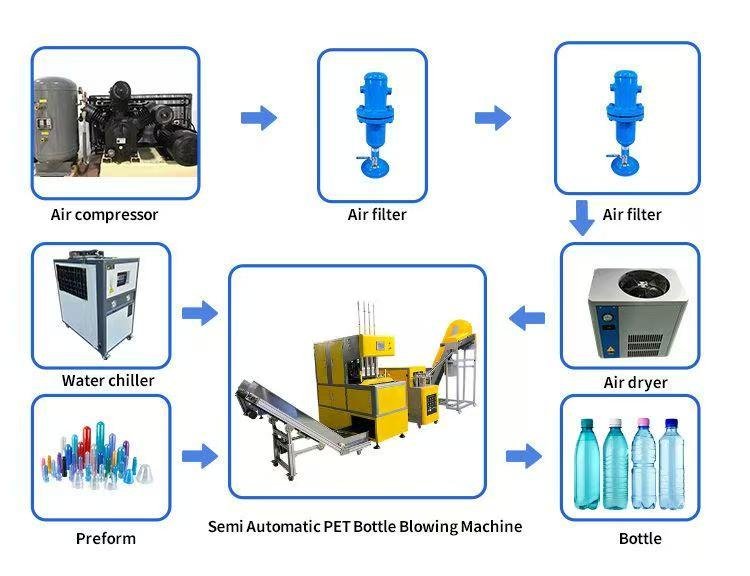

Upgrade your production line with our high-performance bottle blowing machine designed for premium PET packaging. Powered by intelligent heating technology and fast, stable molding, it delivers flawless PET bottles with exceptional clarity and strength. Engineered for efficiency.

Our blow molding machine reduces energy use, boosts output, and keeps your operation running profitably. Ideal for water, beverage, and household product manufacturers seeking reliability, speed, and superior bottle quality. Choose our bottle blowing machine to accelerate your business growth and stay ahead of the competition.

Key Features

High Efficiency and Output: 200-250BPH

Fast Production Rates: Capable of producing a high volume of bottles per hour, ensuring optimal productivity.

Continuous Operation: Designed for long-term, continuous use with minimal downtime.

Advanced Blowing Technology:

Precision Molding: Utilizes advanced molding technology to produce bottles with consistent quality and uniform thickness.

Versatile Bottle Sizes: Easily adjustable to produce bottles of various sizes, from 500ml to 2000ml.

Energy Efficiency:

Low Energy Consumption: Incorporates energy-saving technologies to reduce power usage without compromising performance.

Efficient Heating System: Advanced heating systems ensure uniform heating of preforms, improving bottle quality.

User-Friendly Design:

Intuitive Control Interface: Features a touch-screen control panel for easy operation and monitoring.

Quick Changeover: Designed for quick and easy mold changeovers, minimizing downtime and enhancing flexibility.

Robust Construction:

Durable Components: Built with high-quality materials to ensure long-term reliability and durability.

Low Maintenance: Requires minimal maintenance, reducing operational costs and maximizing uptime.

Quality Assurance:

Consistent Quality: Ensures each bottle meets strict quality standards, with uniformity in shape and thickness.

Defect Detection: Integrated systems to detect and reject defective bottles, ensuring only the highest quality products are produced.

Our Advantages

- User-Friendly

- Food Grade Material

- High-Efficiency

- Energy Efficiency

- Low Energy Consumption

- Advanced Technology

Pre-sales Advice

Our Pre-sales Consultation Services Are Designed To provide You With All The Information.

Installation Service Provided

Online Service And Enginner Oversea Service

Deliver Time

20-60 Days After Receiving The Deposit

Main Technical Parameters

Main parameter: | ||

Model | HG-C1 | |

Main machine | Product material | PET |

Volume | 3000-10000ML | |

Theoretical output | 200-250PCS/H | |

Preform length | 150mm-300mm | |

Preform inner diameter | Φ30mm-100mm | |

Max. mould plate Dimension(L x W) | 450x550mm | |

Max.mould thickness | 450mm | |

Clamping force | 120KN | |

Mould opening stroke | 350mm | |

Blowing Air Pressure | <=3.0 Mpa | |

Working Pressure | <=1.0mpa | |

size and weight | Main machine (L x W x H) | 175*75*170cm |

Main machine weight | 800Kg | |

Heater (L x W x H) | 187*63*145cm | |

Heater weight | 280Kg | |

Power | 7kw | |

If you want to know more about operation, please click: https://jmhgmachine.com/how-to-operate-the-semi-automatic-bottle-blowing-machine/